Continuous Inkjet Printer (CIJ)

Fluid based, non-contact printing of up to five lines of text, linear and 2D bar codes, or graphics, printed on a variety of packaging types including stationary packaging via traversing systems.

Liên hệ với chúng tôi

Liên hệ với chúng tôi ngay hôm nay để được tư vấn miễn phí & xem mẫu thử:

Videojet Vietnam:

Mobile/Zalo: +84 83 805 1033

- Brochures

- Spec Sheets

- White Paper

- Line Integration

- Videos

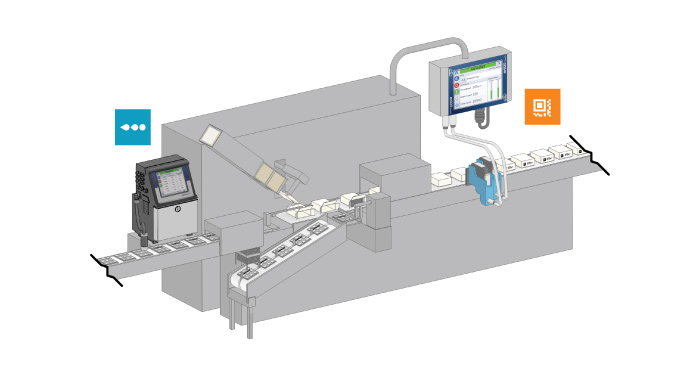

- Cartoner

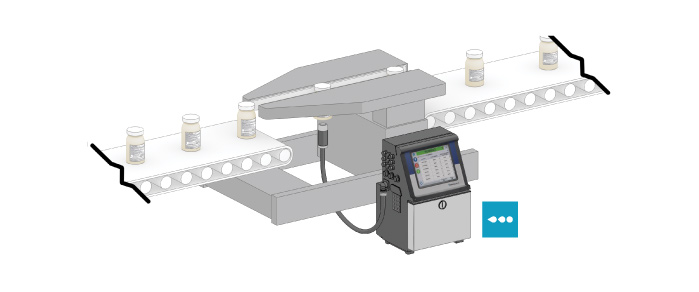

- Sidegrip Conveyor

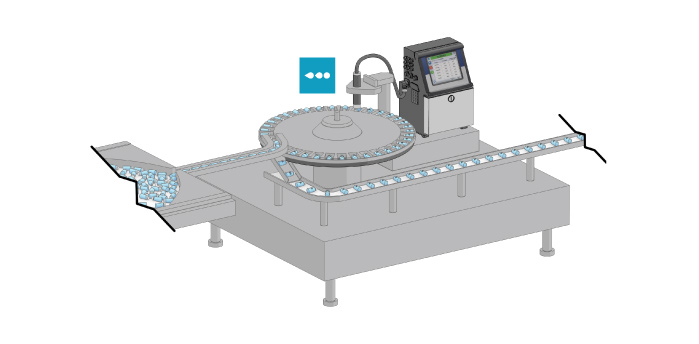

- Vial/Ampule Starwheel

Coding may occur in several locations, either integrated into the cartoner itself or on the outfeed conveyor. Printing may also occur upstream of the cartoner on the primary pack as required.

Continuous inkjet (CIJ)

Fluid based, non-contact printing of up to five lines of text, linear and 2D bar codes, or graphics, printed on a variety of packaging types including stationary packaging via traversing systems.

Thermal inkjet (TIJ)

Ink-based, non-contact printing using heat and surface tension to move ink onto a package surface. Generally used to print 2D DataMatrix and other bar codes.

Simple coder integration with a sidegrip conveyor allows for marking of either visible or covert codes on the top or bottom of pharmaceutical bottles. Downstream code verification can be easily accommodated while the bottle is engaged by the conveyor.

Continuous inkjet (CIJ)

Fluid based, non-contact printing of up to five lines of text, linear and 2D bar codes, or graphics, printed on a variety of packaging types including stationary packaging via traversing systems.

Drop placement accuracy is critical for traceability codes placed on small pharmaceutical packaging, common in brite stocking applications. The highly precise motion of the starwheel offers the ideal material handling for this application.

Continuous inkjet (CIJ)

Fluid based, non-contact printing of up to five lines of text, linear and 2D bar codes, or graphics, printed on a variety of packaging types including stationary packaging via traversing systems.